EOTech LBC (Visible Red LASER)

EOTech LBC (Visible Red LASER)

UPC: 672294600503

DISCONTINUED

EOTech 512.LBC

(512.A65 + LBC LASER Battery Cap)

UPC: 672294600480

DISCONTINUED

![]()

EOTech LBC2 (Visible Red LASER + Covert Infrared LASER)

EOTech LBC2 (Visible Red LASER + Covert Infrared LASER)

UPC: 672294600510

DISCONTINUED ZERO STOCK Available

EOTech 552.LBC2 (552.A65 + LBC2 LASER Battery Cap)

EOTech 552.LBC2 (552.A65 + LBC2 LASER Battery Cap)

UPC: 672294600497

DISCONTINUED - ZERO Stock Available

The ever popular and durable EOTech 512 has been transformed. The addition of an integrated aiming laser improves the operator's target acquisition times and aiming capabilities, making this new 512.LBC ideal for home defense or training situations.

The ever popular and durable EOTech 512 has been transformed. The addition of an integrated aiming laser improves the operator's target acquisition times and aiming capabilities, making this new 512.LBC ideal for home defense or training situations. An integrated accessory port allows for the use of a remote pressure switch that is available separately.

These EOTech sights are proudly manufactured in the USA

These EOTech sights are proudly manufactured in the USA

* 512.A65 Reticle is a 65MOA circle with 1 MOA Aiming Dot

* Single AA Battery Model (Supports Lithium or Alkaline)

* Includes rugged aluminum hood assembly and knobbed, tool-less mounting bolt

* Battery cap and latch are eliminated and replaced with a simple O-ring, tethered cap; better sealing is achieved

* Average battery life at brightness level 12 is roughly 600 Hours / 1,000 Hours for Lithium

* Interfaces to 1" Picatinny (MIL-STD 1913) or Weaver Rail

* The 512 Models are NOT Night Vision compatible

| Ordering Information | |

|

LBC 512.LBC |

UPC: 672294600503 UPC: 672294600480 |

| Operation | |

| Optics | Transmission Holography - 100% Parallax Free |

| Magnification | 1X |

| Eye Relief | Unlimited |

| Sealing | Fog proof Internal Optics |

| Waterproof | Submersible to 10' |

| Adjustment (per click) | 0.5 MOA (1/2" at 100 yards) |

| Adjustment Range | +/- 40 MOA Travel |

| Mount (Adjustable for Width) | 1" Weaver or MIL-STD-1913 "Picatinny" Rail |

| Return to Zero | Repeatable to 1 MOA after Re-Mounting |

| Heads-Up Display Window | |

| Optical Surfaces | Anti-Glare Coating |

| Window Dimensions | 1.2" x 0.85" (30mm x 23mm) |

| Front Window Material | 1/8" Solid Glass |

| Rear Window Material | Shatter Resistant Laminate 3/16" Thick |

| Field-of-View (100yds) | 30yds (28m) at a 4" Eye Relief |

| Standard Reticle | 512.A65: 65 MOA Ring and 1 MOA Dot |

| Electrical | |

| Brightness Adj. Range | 146,000:1 brightest to lowest |

| NV Brightness Range: | 1280:1 with NV Switch Engaged |

| Function Button Location | Back |

| Power Source | (2) AA Alkaline, Lithium or Rechargeable Battery |

| Battery Life (At Level 12) | 600 Alkaline / 1,100 Lithium |

| Brightness Settings | 20 Daytime Settings with Scrolling Feature |

| Auto Battery Check Indicator | Flashing reticle upon start-up |

| Auto Shut-down | At 8 hrs- programmable to 4 hrs |

| DIMENSIONS | |

|

Length Width Height |

5.4" (137 mm) 2.0" (50.8 mm) 2.25 (57 mm) |

| Weight | 10.9 oz (310 grams) |

| ENVIRONMENTAL DATA | |

| Temperature Range | -40ºF to 150ºF |

| Max Storage Temp. | -80ºC (176ºF) |

Night Vision Compatibility: NO

*This Holographic Weapon Sight must be exported from the United States in accordance with Export Administration Regulations ECCN 0A987. Diversion contrary to U.S. law is prohibited. In accordance with U.S. law (Title 15 CFR part 746 and Supplement No. 1 to Part 774; and Title 31 CFR) resale/re-export or transfer of Holographic Weapon Sight Models 552, 551, 512, 511, 4X magnifier and 3X magnifier to certain designated countries is prohibited without prior written consent of the U.S. Department of Commerce. The Holographic Weapon Sight Models 553, 557 and 555 are controlled under U.S. International Traffic in Arms Regulations (ITAR) and may not be exported without proper authorization by the U.S. Department of State.

HOOD

Models 511, 512, 551, and 552 are equipped with a protective hood. This hood is pre-assembled at the factory and is non-removable. Should your hood require maintenance please contact our Customer Service Department at (702) 324-6463 or email customerservice@nitevis.com

CAUTION- Tampering of Hood lock screws will void warranty.

BATTERIES

Two (2) commonly available Type N or AA alkaline 1.5 V batteries power your HWS depending on the model. An initial set of batteries comes with your sight. The HWS is designed to maintain constant brightness at a particular setting as the batteries drain down. The reticle brightness will not fade gradually as the batteries run down but rather shut down abruptly. The first indication of the batteries draining is the reticle blinking when the unit is turned on (see Electronic Features 1).

Another indication of low batteries is the reticle pattern blinking off and on during recoil. With high recoil guns, this can occur before the battery check indicates low battery condition. If the reticle pattern blinks off and on during recoil or turns off suddenly, replace the batteries. Please read and follow the battery replacement and battery check procedures described in your user Operator's Manual.

Alkaline batteries from different manufacturers are not all constructed the same way. Tests show some brands are more susceptible to degradation by the shock of recoil. We recommend the use of Eveready Energizer batteries with the HWS. It is always good practice to replace the batteries with a fresh set before a mission.

CAUTION-There is a 12 V battery that is approximately the same size as the Type N 1.5 V battery. DO NOT USE 12 V battery. They will severely damage the sight.

Two (2) common AA size batteries power your Model 512 HWS. An initial set of AA size alkaline batteries comes with your sight. EOTech recommends using Energizer Alkaline or Lithium AA batteries. Lithium AA batteries offer longer life, particularly at temperatures below freezing. For this reason Lithium AA batteries are recommended for cold weather operations. However, we should note that the battery checking function which is based on the characteristics of Alkaline batteries does not operate properly with Lithium batteries.

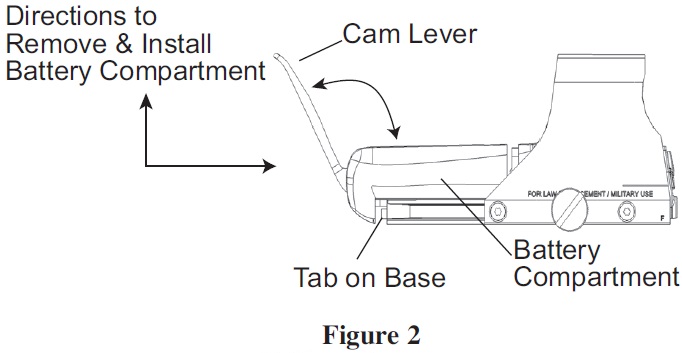

REPLACING BATTERIES

Remove the battery compartment by lifting up on the locking cam lever and carefully sliding the battery compartment away and up from the sight housing (Figure 2) . After the battery compartment is removed, slide the batteries out and replace them with a fresh set. The labels on the bottom of battery compartment show the correct battery orientation. Always make sure the gasket is free of dirt before the battery compartment is re-installed or the water proofing may be compromised. To re-install the battery compartment, point the sight towards the ground and slide battery compartment onto the base. Make sure there is enough clearance between the contact and the batteries to avoid bending the contacts. Hold the battery compartment down firmly against the base and close the locking cam. Before you push down on cam lever, make sure the battery compartment sits all the way down and is parallel to the base. Verify correct battery installation immediately by turning on the sight and checking if the holographic reticle appears. If the batteries are left in the sight backwards, they will be drained of their power.

ELECTRONIC FEATURES

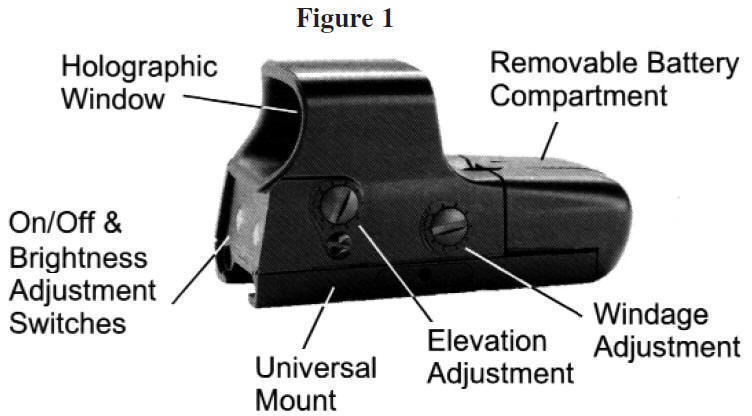

All electronic controls are via push-button switches located at the rear of the unit housing as shown in Figures 1. To ensure proper operation of the push button switches we recommend pressing firmly on the center of the switch.

1. ON/ Auto-Battery Check

Depressing the Up or Down Arrow push-button switches will turn the sight ON at Level 12. See step 4 under this section for description of Auto shutdown. The sight will automatically perform a battery check every time it is turned on. If the batteries have less than 20% of life left, the sight will turn on with the reticle image blinking on and off for 5 seconds. If the remaining battery life is more than 20%, the sight will turn on with a steady reticle pattern. The battery condition can be checked any time by turning the sight off and back on.

2. OFF

To turn the sight off depress both UP and DOWN arrows simultaneously. Verify by looking through heads-up display window.

3. Brightness Adjustment

Push-button switches vary the brightness intensity of the holographic reticle pattern. Depressing and releasing the push-button switches moves the brightness level UP or DOWN one (1) step from the previous setting. Depressing and holding the up arrow or down arrow switch will change brightness level up or down continuously in steps. There are twenty (20) brightness settings providing a dynamic range of 146,000:1 from the lowest setting to the highest setting.

4. Auto Shutdown

The HWS is equipped with auto shutdown capability. If the sight is turned on by depressing the UP button, it will automatically shut itself OFF 8 hours after the last push-button control is used. The sight will automatically shut OFF after 4 hours if it is turned on by depressing the DOWN button.

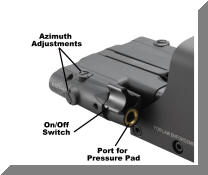

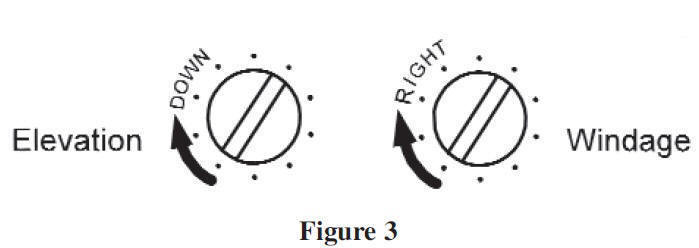

WINDAGE AND ELEVATION ADJUSTMENTS

Your HWS features click mechanisms for elevation and windage adjustments. The elevation and windage adjustment are located on the Right-hand side of the sight (Figure 1). The knob towards the front is your windage adjustment and the knob towards the rear is your elevation adjustment (Figure 1). Both of these adjustment mechanisms are grooved with a slotted screw head and require the use of a screwdriver, coin, or spent brass to turn.

To move the point of impact RIGHT, turn the windage adjustment screw clockwise; to move the point of impact LEFT, turn the windage adjustment screw counterclockwise .

The elevation and windage adjustments have been initially set at the factory such that the line of sight to the center of the reticle is parallel to the mounting rail on the weapon. The sight should be close to being at zero with a properly installed mounting rail. Please do not turn the adjustments before mounting the sight on the firearm. Be sure to check that the mount and the sight remain secured after the first shots are fired.

CAUTION-When encountering a sudden increase in resistance in these adjustments, the end of the adjustment range has been reached. DO NOT TRY to turn the adjustments any farther or serious damage may occur to the sight.

LASER SAFETY ISSUES

The HWS is a Class II laser product. The Class II level illuminating beam, however, is completely blocked by the housing. The only laser light accessible to the eye is the image beam and is at a power level within the limit of a Class IIa laser product. The illuminating beam can become accessible to the eye if the housing is broken. Turn the sight off immediately and return the broken unit to the factory for repair.

MOUNTING

1. Locate the bolt and locking bar on the underside of the sight. Loosen the bolt and the locking bar with the Allen wrench (7/64")

2. Place the bolt within a groove on the top of the rail. Individual preference and the specific firearm determine the optimal positioning to any specific groove on the rail.

3. Make sure the bolt is inserted fully into the mounts groove and push the sight as far forward as possible. Tighten bolt.

NOTE 1: Loosen bolt just enough to mount and dis-mount the sight.

Do not back bolt out completely to avoid losing the mounting hardware.

NOTE 2: A Picatinny (MIL-STD-1913) rail cannot be installed directly on some weapons. EOTech sells mount adapters to provide a standard Picatinny rail for various weapons used in todays military and law enforcement applications. Contact a factory representative if you are unclear on the mounting adapter you should use on your weapon.

BORE SIGHTING AND ZEROING

Bore sighting is a good preliminary procedure in achieving proper alignment of your sight to the firearm. If the rail is not mounted parallel to the barrel, major elevation adjustments may be accomplished by shimming the dovetail rail. It is important not to use the elevation adjustment of the sight for major adjustments. Your sights internal elevation and windage adjustments should be reserved for fine-tuning to achieve zero at the called for distance. Final zeroing of your firearm and sight should be done with live ammunition and based on your expected shooting distance. If you anticipate most of your shooting at short range, zero in at 50 yards (45.7m). Groups of three to six shots will be useful for averaging the point of impact.

FCC COMPLIANCE

The HWS complies with Part 15 of the FCC Rules. Operation is subject to the following conditions:

(1) this device may not cause harmful interference and

(2) this device must accept any interference received, including interference that may cause undesired operation.

MAINTENANCE AND CARE

Your HWS is a precision instrument that deserves reasonably cautious care.

The following tips are provided to ensure long lasting use of the sight.

1. The optical system and the window are coated with anti-reflection material. When cleaning the glass surfaces, first blow away any dirt and dust. Fingerprints and lubricants can be wiped off with lens tissue or a soft cotton cloth, moistened with lens cleaning fluid or glass cleaner sold in any camera store. Never clean the glass surface with a dry cloth or paper towel; always dampen the glass surfaces prior to cleaning

2. All moving parts of the sight are permanently lubricated. Do not try to lubricate them.

3. No maintenance is needed on the sights surface, except to occasionally wipe off with a soft cloth. Use only a water-based cleaner such as glass cleaner, ammonia, or soap and water. Never use any solvent-type cleaner such as alcohol or acetone.

4. Never disassemble the sights optical assembly. The optical cavity is purged, nitrogen filled, and sealed to achieve fog proof performance.

Disassembly will void the warranty.

REPAIR

Send to:

L-3 EOTech

ATTN: Service Department

1201 E. Ellsworth Road

Ann Arbor, MI 48108 USA

You can contact EOTechs Customer Service Department at:

Phone: (734) 741-8868, and press Option 8, or visit their webpage www.L-3com.com/eotech

Email: general@L-3com.com

To Ensure proper operation of the push button switches we recommend pressing firmly on the center of the switch

If your HWS should need repair, please contact EOTech's Customer Service Department at the number shown above to receive a return authorization number for repair. Send the sight and return authorization number to the address above and include your name, address, and telephone number, as well as a written description of the problem you are encountering. Also, include your receipt at the time of purchase. Whenever possible, ship the sight in its original box.

The HWS is equipped with mounting hardware to attach to a standard 1" dovetail or Picatinny (MIL-STD-1913) style rail. To achieve the best results and accuracy, the HWS must be mounted properly. The rail needs to be as parallel as possible to the bore to permit the maximum elevation and windage adjustments. We strongly recommend you have the rail installed by a qualified gunsmith. To mount the sight, please follow these steps.

The elevation and windage adjustments are shown in Figure 3. For both elevation and windage, each click will change the bullets point of impact 1/2 Minute of Angle (MOA), which translates to 1/4 inch at 50 yards (0.64 cm at 45.7 m), 1/2 inch at 100 yards (1.3 cm at 91.5 m). Also, one full rotation of either knob will change your point of impact 10 MOA. This translates into 5 inches at 50 yards (12.7 cm at 45.7 m), 10 inches at 100 yards (25.4 cm at 91.5 m). To move the point of impact UP, turn the elevation adjustment screw counterclockwise; to move the point of impact DOWN, turn the elevation adjustment screw clockwise.

EOTech's Frequently Asked Questions Page

HWS Features

Electronic Features

The HWS uses state-of-the-art digital electronics design. Twenty brightness levels (plus 10 additional NV settings) ensure proper brightness control in either low light or very bright sunlight. An on-board microprocessor provides automatic battery check indicator, up/down brightness scrolling and programmable auto shutdown features. All electronics are fully encapsulated in shock absorbing resin compound.

The HOLOgraphic Advantage

The holographic patterns have been designed to be instantly visible in any light, instinctive to center regardless of shooting angle, and to remain in view while sweeping the engagement zone. Reticles are designed as large, see-through patterns to achieve lightning quick reticle to target acquisition without covering or obscuring the point of aim.

Heads Up, Full View

The HWS employs a true Heads-Up Display that eliminates blind spots, constricted vision, or the tunnel vision associated with tube sights. All user controls are flush to the HWS's streamline housing with no protruding knobs, battery compartments or mounting rings blocking vision at the target area. True, 2 eyes open shooting is realized. Instant threat identification is achieved by maximizing the operator's peripheral vision and ultimately gaining greater control of the engagement zone.

The Magic of Holography

The Magic of Holography

In holography, all the information required to reconstruct the reticle image is recorded everywhere in the Heads-Up display window. If the window is obstructed by mud, snow, rain, etc., the HWS remains fully operational, with point of aim/impact being maintained. Even in such extreme cases where the laminated window is shattered, the HWS is fully functional! As long as the operator can see through any portion of the window, the entire reticle pattern is visible on target...the operator can still engage with confidence.

HWS Benefits

Extreme Durability

Extreme Durability

The HWS has been designed and tested to provide consistent, reliable performance even in the most hostile operational environments. It is waterproof, fog proof, shockproof, and temperature proof.

The HWS is designed to withstand Mil-Spec drop tests and still remain fully operational and hold zero. The HWS has been extensively tested in a punishing recoil simulator generating 3,500 G's of acceleration in less than 0.5 milliseconds (the recoil of a .454 Casull revolver) as well as various environmental chambers).

The Heads Up Display is constructed with a 3 layer, shatterproof laminate glass that is 3/16" thick for added durability. Additional protection of the Heads Up Display is provided with a "roll bar" ruggedized hood.

No Revealing Signature

No Revealing Signature

The HWS does not emit any muzzle side position revealing light signature...the projected reticle pattern is visible only to the operator. Even Gen III night vision equipment cannot detect muzzle side signature of the operator's position.

All optical surfaces are flat and treated with anti-reflective coatings eliminating additional muzzle side signature due to reflective glare. No need for costly glare elimination filters that reduce the effective light transmission and further dim the target area.

How to make a Hologram

Holography is described scientifically as a wave front reconstruction process. Unlike a camera which forms and records the two-dimensional image of an object on film, a hologram records and reconstructs the light field propagating from a three-dimensional object to the viewer. A good analogy is the recording and play back of sound. The sound waves (e.g. music) are encoded and recorded on a disk. Upon proper decoding, the original sound waves are reconstructed. With holography, the field is encoded in the form of an interference pattern and recorded as refractive index variations on a clear window. The decoding is achieved by illuminating the hologram with laser light and the light field that was propagating from the object scene to the hologram window is reconstructed. Thus, a viewer cannot tell if the three-dimensional image he sees is "live" or a holographic reconstruction.

The Holographic sight makes use of the capability of a hologram to construct a three-dimensional image to produce a reticle that is projected out to the target plane. This is achieved by using a large, high quality aberration free lens to project the pattern as illustrated. The reticle image could be of any light pattern, any geometric shape or size, and produced in either 2 dimensional or 3 dimensional form. The holographic reticle is uniformly bright and distortion-free regardless of image size. A parallax free image is created with a large and bright aiming pattern allowing quick target acquisition, particularly in close quarter combat situations. At the same time, the HWS can produce an aim point as small as the human eye can resolve to achieve the highest aiming accuracy possible without magnification.

EOTech Limited Warranty

All EOTech products are created with pride in the USA. More importantly, they are manufactured with our customer's satisfaction in mind. EOTech warrants every product to be free from defects in materials and workmanship for a period of 2 years from the original date of purchase.

EOTech will promptly repair or replace, at its option, any product which is defective in material or workmanship, without charge. All of the costs that are associated with the product shipment will be incurred by the owner. EOTech products, to be repaired under the warranty service, must have a valid return authorization number, which purchasers may obtain by clicking Return Authorization Request Form or calling EOTech's Repair & Service Department at (734) 572-2176 during normal business hours. All products must be sent to:

L-3 EOTech Repair & Service Department

1201 E. Ellsworth Road

Ann Arbor, Michigan 48108

Reference: RA#

This warranty does not cover defects caused by improper handling, installation or maintenance, abnormal use or unapproved alterations. EOTech shall not, in any event, be liable for any damages, including any lost profits, lost savings or any other incidental or consequential damages arising out of the use or inability to use such products. This warranty gives the owner certain legal rights, and possibly other rights, which vary from state to state.

Troubleshooting

In this section you will find troubleshooting techniques. If these solutions do not solve the problem, please contact KERIF Customer Service Department at customerservice@nitevis.com or by calling (702) 324-6463.

The sight will not power up:

Ensure the batteries are inserted properly according to the diagram on the bottom of the battery cap.

Replace the batteries with new, unused batteries that contain a full charge.

Inspect the battery contact points in both the battery cap and on the sight itself. These contact points are spring loaded and surrounded by a rubber gasket that may catch the spring. Move the contact points around and ensure they are at or above the surface of the rubber gasket.

Reset the electronics by removing any source of power for approximately two minutes. This will allow a capacitor in the electronics housing to drain of power, resetting the electronics. Reconnect the batteries and operate the sight as normal.

Check the battery contacts for corrosion or wear. Clean the contacts.

The reticle is fuzzy/ has a 'halo' effect/ has more than one reticle:

The reticle is naturally pixilated and the outer circle will appear to be made up of many small dots. The center circle will still be distinguishable as one dot.

Lower the brightness level of the reticle. This fault is generally caused by the reticle brightness being too high. The reticle is not designed to be so bright as to block the target.

The reticle is projected onto your target plane. You must focus on it like you would any other object at that distance. Do NOT focus on the sight housing like other reflex sights; focus on your target. The outer ring is designed to be a reference to center, similar to a ghost ring.

If you wear corrective lenses for nearsightedness, you will require them to see the reticle in focus as it is projected onto the target plane. If you wear bifocals or have astigmatism, you may see a distorted reticle.

Check with others who have used the sight, and compare what you see to ensure it is not your focal acuity prior to turning the sight in for repair.

The reticle is flashing/ flashing on and off/ unit turns off during recoil:

This is the low battery indicator. Replace the batteries.

If the batteries are low, the weapon platform may still cause the reticle to flash on and off, even before the low battery indicator takes effect. Replace the batteries.

Replace the battery with Energizer brand batteries. These have proven to be the most effective to withstanding a consistent amount of recoil. Many brands of batteries deteriorate faster than others and can result in these failures.

There is a streak in the reticle/ the reticle is dim/ the reticle fades in parts of the window:

Replace the batteries.

Check with others who have used the sight, and compare what you see to ensure it is not your focal acuity prior to turning the sight in for repair.

Contact Customer Service.

I am missing a bolt/ have broken a bolt/ have broken a latch:

Contact Customer Service